Solid disulfide Silane Crosile75C for tyre industry

Considerable scorching safety than Silane Crosile 69C

Synonyms

Si-75C,Silane HP1589,Silane A-1289, Silane JH-75

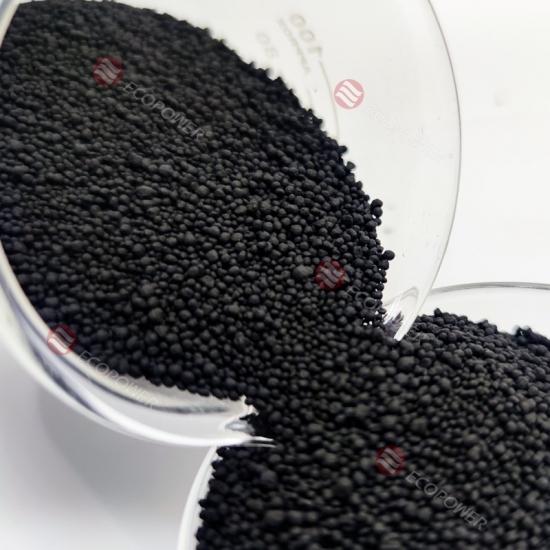

The mixture of Bis-[3-(triethoxysilyl)-propyl]-disulfide (50%) and Carbon Black (50%)

Di-(3- ethoxy silane propyl) -disulfide and carbon black mixture

Crosile®75C is a blend of Bis-[γ-(triethoxysilyl)-propyl]-tetrasulfide(50%) and Carbon Black (50%)

Specifications

|

Test Items |

Target Values(Spec. Limits) |

|

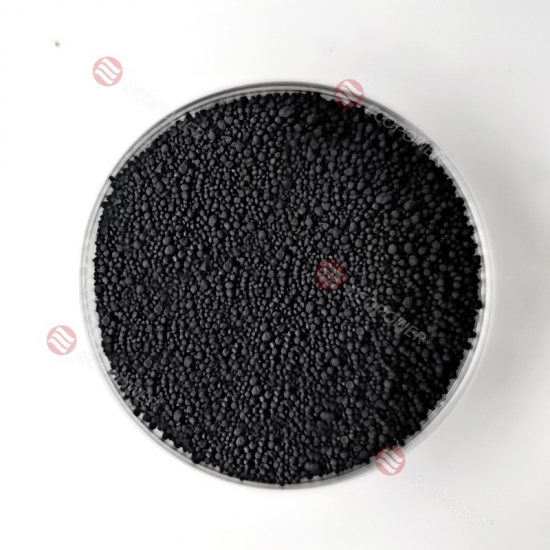

Appearance |

Black Granular |

|

Sulfur Content % |

12 ± 1 |

|

Ash Content % |

11.5±1 |

|

Heating loss in 105°C |

≤2.0% |

Application

- Crosile®75C is a solid admixture of Crosile®75 and carbon black. It not only performs the same function as Crosile®75 but also can be used more easily. It is used to improve physical and mechanical properties of vulcanization.

- Crosile®75C is able to markedly improve tensile strength, tearing strength and abrasive resistance and reduce compression set of vulcanization. In addition, it is able to reduce the viscosity and improve the process ability of rubber products.

- Crosile®75C is suitable for some polymers such as NR, IR, SBR, BR, NBR and EPDM.

- Crosile®75C’s active principle contains low active disulfide-bond functional group. It can offer considerable scorching safety.