Silane VTMOEO Crosile172 Reinforced resin bond in fiberglass

Chemical Properties

Silane Crosile® 172 acts as an adhesion promoter for various mineral-filled polymers, improving their mechanical and electrical properties, especially after exposure to moisture. Once combined with inorganic fillers.

Silane Crosile® 172 makes the filler surface hydrophobic. This effect increases the compatibility of the filler with the polymer matrix, resulting in better dispersion, reduced melt viscosity, and easier processing of the filled plastic.

Polymer dispersions modified with silane Crosile® 172 exhibit higher bond strength and wet scrub resistance in wet conditions.

Synonyms (Equivalent)

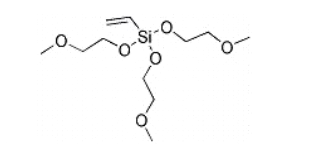

6-Ethenyl-6-(Methoxyethoxy)-2,5,7,10-Tetraoxa-6-Silaundecane; Tris(methoxyethoxy) Vinylsilane;

(Tris (Beta-Methoxyethoxy))vinylsilane; Tris(2-Methoxyethoxy)vinylsilane; Vinyltris(Beta-Methoxyethoxy)Silane

Specification

|

Test Item |

Target Values (Spec. Limits) |

|

Purity |

≥ 98.0% |

|

Density (g/cm3, 25℃) |

1.040 ± 0.02 |

|

Refractive index (25℃) |

1.430 ± 0.05 |

|

Cl content ppm |

<15 |

Application

1. Improve electrical performance and mechanical strength:

As a surface treatment agent for clays and siliceous inorganic fillers

2. Enhance the mechanical strength of composite materials:

It will reduce the water absorption, electrical properties and mechanical strength of the cross-linked polyester molding material.

3. In fiberglass applications:

Reinforced resin bond