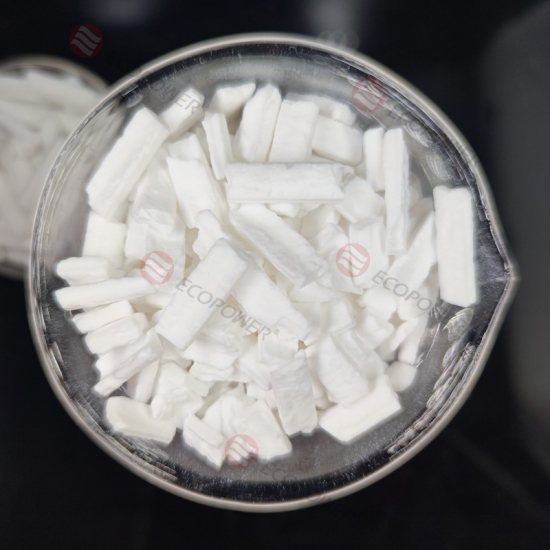

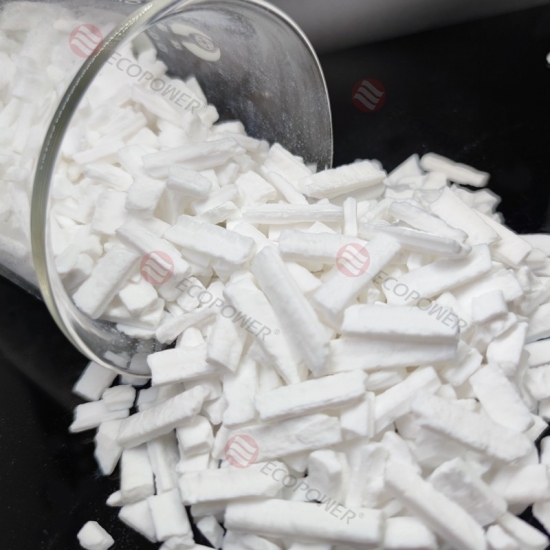

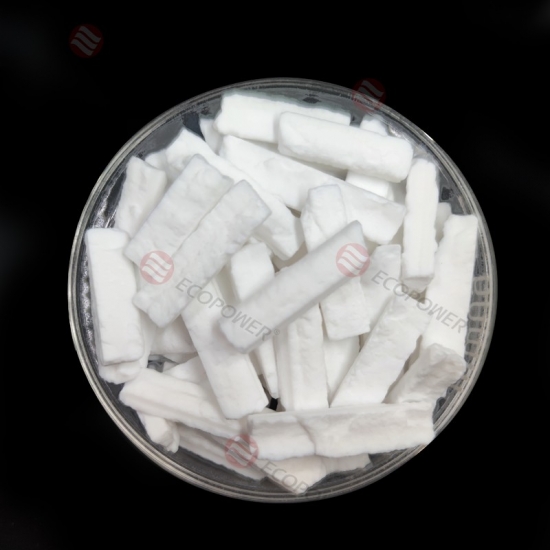

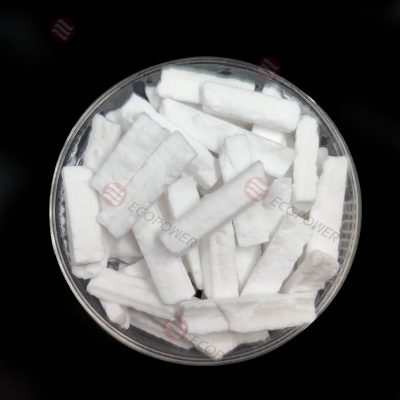

175GR White Granular Precipitated Silica in Rubber Shoe Sole

Better Transparency White Carbon Granular Precipitated Silica for rubber shoe sole and tire industry

Product Name

Amorphous Silica, SiO2, White carbon black, Precipitated Silica, Silica, Silicon Dioxide, Reinforcing filler, NV2, NV3.

Chemical Properties

White powder or granular form, precipitated silica is made of sodium silicate with sulfuric acide through hydrolysis.

It can be dissolved by NaOH,HF. Other kinds of acid, water and solvents cannot dissolve the product.

Specifications

|

Items |

Specification |

|

Appearance |

White Granular |

|

Loss at 105°C 2h % |

4.0-8.0 |

|

Igniting Loss 1000°C 2h % Max. |

7.0 |

|

DBP absorption Value cm3 /g |

2.00-2.80 |

|

60Mesh sieve residue % Min |

75 |

|

pH Value (5% aqueous suspension) |

6.0-8.0 |

|

SiO2 % Min |

97 |

|

BET specific surface area m2/g |

155-185 |

Application

Precipitated silica 175GR is made as a semi-reinforcing filler in non-black SBR compounds.

White Carbon Black Granular 175GR has excellent reinforcement performance and surface activity in white and light-colored fillers and is widely used in rubber soles, tires, rubber pipes, rubber tapes, cost, rubber seals and other products.

175GR produced an improvement in the wear resistance of these compounds. The formulas, based on a combination of SBR, silica, and high styrene resin, provided hitherto unavailable levels of abrasion and tear resistance.

These benefits, together with the elimination of the floor marking deficiency of black soles, led to the gradual replacement of carbon black and clay in both hard and soft soling.

Beyond the selling and footwear markets, silica's adaptability to compounding in color made it a valuable new resource in belting, hose, and other mechanical goods products.