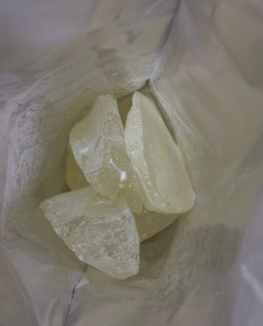

Potassium Soap of Disproportionated Rosin DRS K 80

Chemical Properties

Potassium Soap of Disproportionated Rosin is produced by disproportionated rosin reacting with Potassium hydroxide.

Specifications

| Test Items |

Specification |

|

Solid Content(%) |

80±1 |

|

Color(Gardner), Max |

6 |

|

PH(25℃) |

9.2-9.8 |

|

Potassium Abietic(%), Max |

0.5 |

|

Potassium Dehydroabietic(%), Min |

38.0 |

|

Chloride(as KCL) (%), Max |

0.25 |

|

Unsaponifiable Material(%), Max |

8.0-13.0 |

Application

Potassium Soap of Disproportionated Rosin can be used as emulsifier for emulsion polymerization in producing SBR, Neoprene NBR synthetic rubbers and ABS plastics. It can improve the stickiness and plasticity of synthetic rubbers, so as to increase its strength of heat resistance, tearing and abrasive resistance.