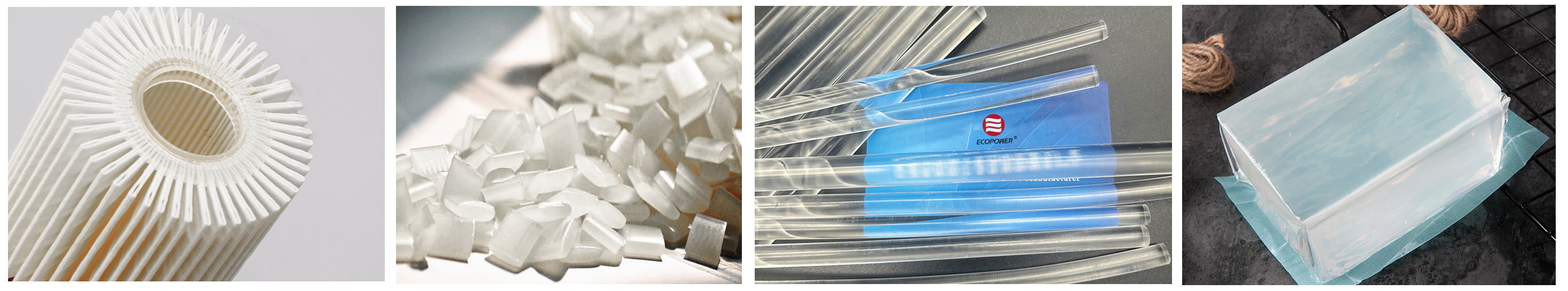

Hydrogenated resin is often used as a component in hot melt adhesives. Hot melt adhesives are thermoplastic materials that are solid at room temperature but become liquid when heated. When hydrogenated resin is added to hot melt adhesive formulations, it serves several purposes.

Improved Adhesive Properties

Hydrogenated resin enhances the adhesive properties of the hot melt adhesive, providing better bonding strength and adhesion to different substrates.

Increased Flexibility

The addition of hydrogenated resin can improve the flexibility of the hot melt adhesive, making it more suitable for applications where flexibility is crucial, such as in packaging materials.

Temperature Resistance

Hydrogenated resin can contribute to the heat resistance of the hot melt adhesive, ensuring that the adhesive maintains its integrity and performance at elevated temperatures.

Reduced Odor

Hydrogenated resins are often used to reduce the odor of hot melt adhesives, making them more suitable for applications where odor may be a concern, such as in the production of food packaging.

Compatibility

Hydrogenated resin can enhance the compatibility of various components in the hot melt adhesive formulation, leading to a more stable and homogeneous product.

Specifications

| HY DCPD |

HY 6100 |

HY 6110 |

HY 6120 |

Test Method |

|

Appearance |

Water White | Water White | Water White |

Eyeballing |

|

Softening Point (°C) |

105-110 |

100-110 |

110-120 |

ASTM E 28 |

|

Yellow Index |

≤5 | ≤5 | ≤5 |

ASTM D 1925 |

|

Color Gardner |

0-1 | 0-1 | 0-1 |

ASTM D 974 |

|

Thermal Stability (200°C, 5h, YI) |

≤10 |

≤10 |

≤10 |

ASTM D 1925 |

|

Melt viscosity (180°C, cPs) |

130-200 |

- |

- |

ASTM 3236 |