Chlorosulfonated Polyethylene CSM 30 in Anti-corrosion Paint

CSM Rubber, Hypalon Rubber

Type

CSM 30

Chemical Properties

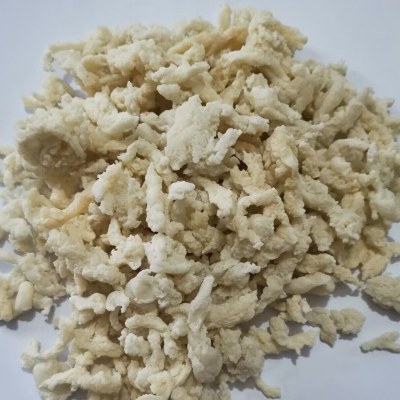

1. CSM 30 rubber is a kind of white material which turns to light yellow or brown, tasteless evenly rubber-shape, and it has the mutual character with rubber which also has its own property.

2. It is non-toxic, non-explosive, open flame burning, auto-extinction after remove.

3. It has excellent ozone resistance, resistance to atmospheric aging, chemical resistance, better physical mechanical, thermal aging resistance and low temperature resistance (-20℃-12℃), oil resistance, flame resistance, abrasion resistance and electrical insulation etc.

Specifications

|

Test Item CSM 30 |

Target Values(Spec.Limits) |

|

Volatile(wt% less or equal) |

1.5 |

|

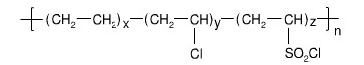

Chlorine content(wt%) |

40-60 |

|

Sulfur content(wt%) |

0.8-1.2 |

|

Mooney viscosity( ML 1+ 4 100 °C ) |

60-90 |

|

Tensile strength (Mpa more or equal) |

25.0 |

|

Elongation at break(% more or equal) |

450 |

Application

CSM Rubber can use in variety of automotive hose, hose, rubber compound, special rubber rollers, seals, wire and cable, anti-corrosion coatings, waterproofing membranes, specialty tapes, adhesives and other special rubber products.

CSM 30 is used for hard material coating, pipeline anti-corrosion and anti-corrosion lining of chemical plant and chemical equipment.

It is also used for sluice, underground pipeline, gas cabinet, urea internal coating and outdoor decorative coating.

It has the characteristics of color stability, easy maintenance and long term.