Hydrogenated resins are revolutionizing a variety of industrial applications, including medical adhesives, filter adhesives, and glue sticks. Their unique properties offer enhanced performance and reliability, making them essential for high-quality products in these sectors. This article delves into how hydrogenated resins are transforming these specific applications and the benefits they bring.

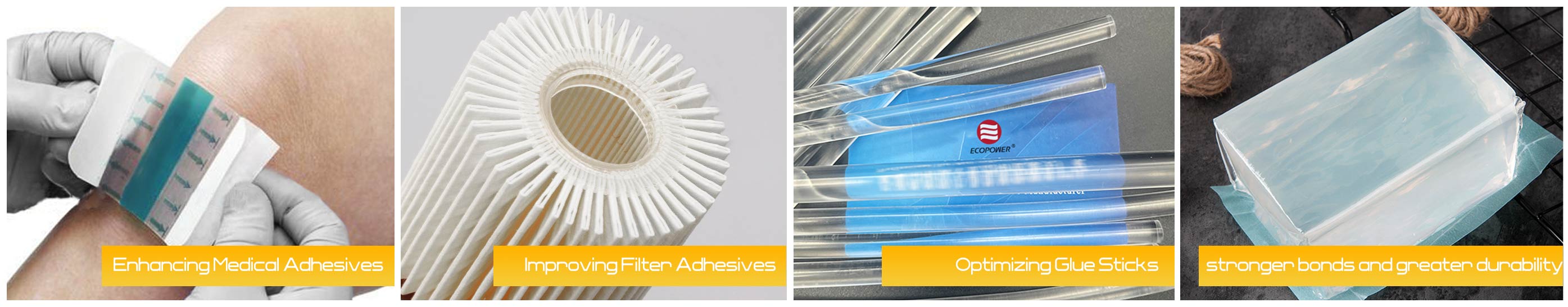

Enhancing Medical Adhesives with Hydrogenated Resins

In the medical field, the demand for high-performance adhesives is critical. Hydrogenated resins are setting new standards by providing medical adhesives with superior strength and biocompatibility. These resins ensure a reliable bond that is resistant to moisture, heat, and chemicals, making them ideal for medical devices and wound care products. Their ability to maintain performance under diverse conditions helps ensure patient safety and product reliability.

Improving Filter Adhesives with Hydrogenated Resins

Filter adhesives benefit significantly from the incorporation of hydrogenated resins. These resins enhance the adhesive's ability to withstand extreme temperatures and harsh chemicals, which are common in filtration systems. The improved thermal stability and chemical resistance lead to better filter performance and longer service life. Whether in air or liquid filtration, hydrogenated resins help maintain the integrity and efficiency of filter adhesives.

Optimizing Glue Sticks with Hydrogenated Resins

Hydrogenated resins also play a crucial role in the performance of glue sticks. By incorporating these resins, manufacturers can achieve stronger, more reliable bonds. The enhanced resistance to heat and chemicals ensures that glue sticks perform well in various applications, from packaging to craft projects. The durability provided by hydrogenated resins contributes to the glue sticks' effectiveness and longevity.

Benefits of Hydrogenated Resins

1. Medical Adhesives: Offer improved bond strength, biocompatibility, and resistance to environmental factors, enhancing safety and effectiveness in medical applications.

2. Filter Adhesives: Provide superior thermal and chemical resistance, resulting in better filter performance and extended product life.

3. Glue Sticks: Ensure stronger bonds and greater durability, making them suitable for diverse industrial and consumer applications.

Recommended Products

Hydrogenated DCPD resin/HY-6100/HY-6110/HY-6120/HY-6130/HY-6140 ![]()

Hydrogenated copolymer resin/HY-52110 ![]()

Conclusion

Hydrogenated resins are transforming the performance of medical adhesives, filter adhesives, and glue sticks. Their exceptional properties, including chemical resistance, thermal stability, and durability, make them invaluable in these applications. By utilizing hydrogenated resins, manufacturers can improve product quality and achieve greater reliability across various industries. Explore the benefits of hydrogenated resins and enhance your product offerings today.